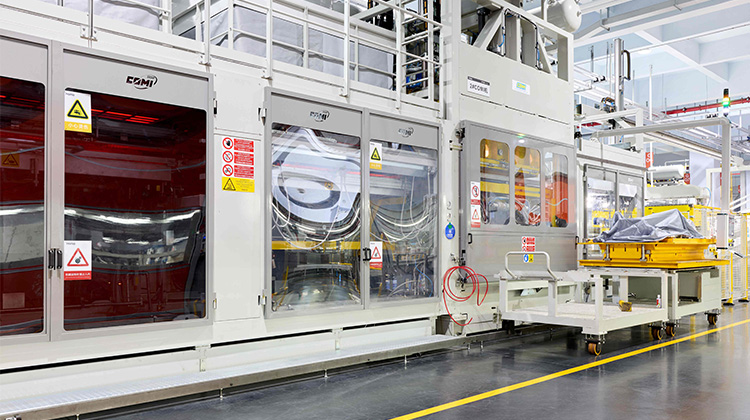

The Vacuum Forming Workshop is not only fully automated, but also designed for noise reduction. Inside, plastic sheets are shaped into refrigerator inner liners through a series of processes including thermoforming and edge trimming. The finished liners are then transported to the next stage via an overhead conveyor, eliminating the need for transport trolleys. The entire workshop is fully enclosed to maintain a controlled and quiet environment. The gate at the bottom, used for mold replacement, also remains sealed during normal operation.

Fully Automation

Stable Cabinet Quality